This page provides design examples for our most popular multi-part lens designs. This page is not meant to limit your imagination. If you have another design idea, give us a call. We’re always excited to take on strange, new challenges.

- Franklin Bifocals, Trifocals & Sector Prisms

- Laminated Prism Segments (Round & Flat) & Channel Lens

- Button Prisms & Pie Prisms

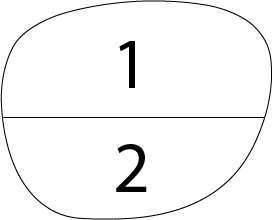

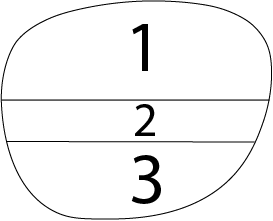

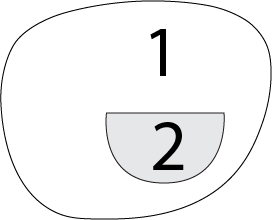

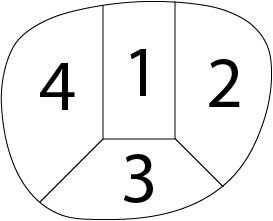

Chadwick’s Franklin Lenses

Franklin lenses look like executive lenses. The difference is that executives are molded lenses, and Franklins are separate lenses that are cut and glued together. Because the Franklin is made of multiple separate lenses, each of the numbered areas can be completely different RX’s. Most often, Franklins are used for RX’s where there is a different amount of prism from distance to near. They can also be used for patients who insist on things like a polarized executive or a photochromic executive.

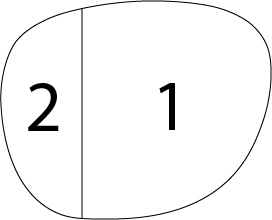

We can also make Vertical Franklins, a popular lens design for field loss associated with hemianopsia. They are also known as sector prisms. However, we strongly recommend you try the scientifically proven Peli Lens™ first.

Chadwick’s Laminated Prisms

Where Franklin lenses are multiple lenses cut apart and glued together at their edges, laminated lenses are stacked, and are adhered together using an optical glue. This gives more versatility in lens design, but is also quite costly. The laminated adds can be used as prism segments, or when readily available add powers don’t meet your needs.

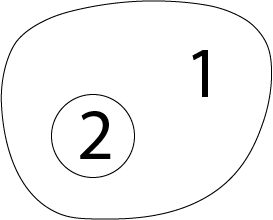

Our Other Kinds of Lenses

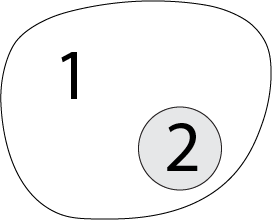

If Franklins or laminates don’t meet your needs, there are a couple of other lens designs we can do.

The first design is the pie prism, which is commonly prescribed for patients with a quadrantanopsia. The second is called a button prism. This is a lens designed for hemianopsia. It is also marketed as a Gottlieb prism or a VFAS system. We recommend you consider the Peli Lens™ peripheral prisms as an alternative to both of these older designs. When constructing the button prism, the carrier lens is drilled, and a high powered prism is glued into the drilled hole. This process is simpler and less costly than laminating.